“John, I find that our suppliers do a poor job in stocking to their agreements and as a result, our customers complain and we lose sales. At Goods Receipt and Purchasing they are just putting out fires, instead of making better agreements. We are losing control on our suppliers and have little opportunity to improve on the agreements. When do you think you can have a vendor rating system up and running?”

Well, John didn’t see that one coming. He had been thinking about the need for a vendor rating system for some time, but simply could not find the time. He was too busy keeping the daily operation running. And now his boss was way ahead of him. But where should he start? In what way and in what system could he best rate the performance of his suppliers?

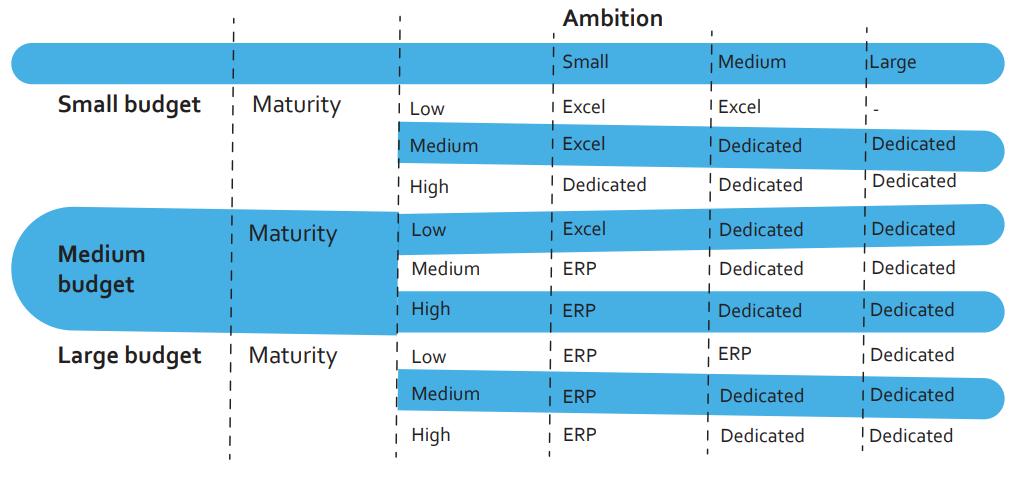

Choosing the right vendor rating system depends primarily on three fundamental issues:

- Scope and ambition

- Budget

- Maturity of the Logistics and Purchasing departments

Scope and ambition

What do you want to achieve with your supplier assessment? If you only have 1 problem, for example, timely deliveries, and don’t expect to ever be interested in solving any other problems, then your system will become reasonably easy to manage. You can still do that on a piece of paper, so to speak.

If your ambitions reach further, because you want to assess several logistical, commercial, financial, and/or quality issues or want to be better prepared for supplier meetings, it becomes a different story. Fortunately, greater ambitions do not necessarily make the required investment much higher. The time required will also increase, but certainly not proportionally.

The number of suppliers also plays a role, of course. If you purchase from 30 suppliers, the effort required to set up an entire system will hardly outweigh the effort. It is only at 50 suppliers/€15 million in purchasing that it becomes worthwhile to be supported by software.

Budget

Not many buyers appear to have a budget. They always have to beg one floor up for money. If Purchasing wants a vendor rating system, it is still very difficult to obtain resources in practice. “Oh dear Peter, you’ve always done that just fine in Excel, haven’t you? We have some other projects to invest in right now. Come back next year.” A year later, it still turns out to be very difficult to get the funding towards some software.

It is smarter to work together with your colleagues from Logistics/Supply chain. They usually have the budget. And a vendor rating system is, in short, equally interesting for both:

– for the buyer to better negotiate improvements with well-founded arguments;

– for Logistics to reduce process disruptions and error costs.

In part two, we briefly discussed the business case: try to get a sense of the potential savings to be gained from supplier assessment using a model. I offer here again for those interested the opportunity to send such a model. Many, to my great surprise, have already requested it. Hopefully, this model will put the available budget somewhat in perspective.

Maturity of the organization

It may seem obvious, but you can have a beautifully designed system with wonderful assessment criteria and ditto results at your disposal, but if the team is not capable of using them, it will be a waste of time and money. Pearls before swine. I have always learned that the internal organization should follow the set ambitions instead of the other way around, but in practice this is still quite difficult.

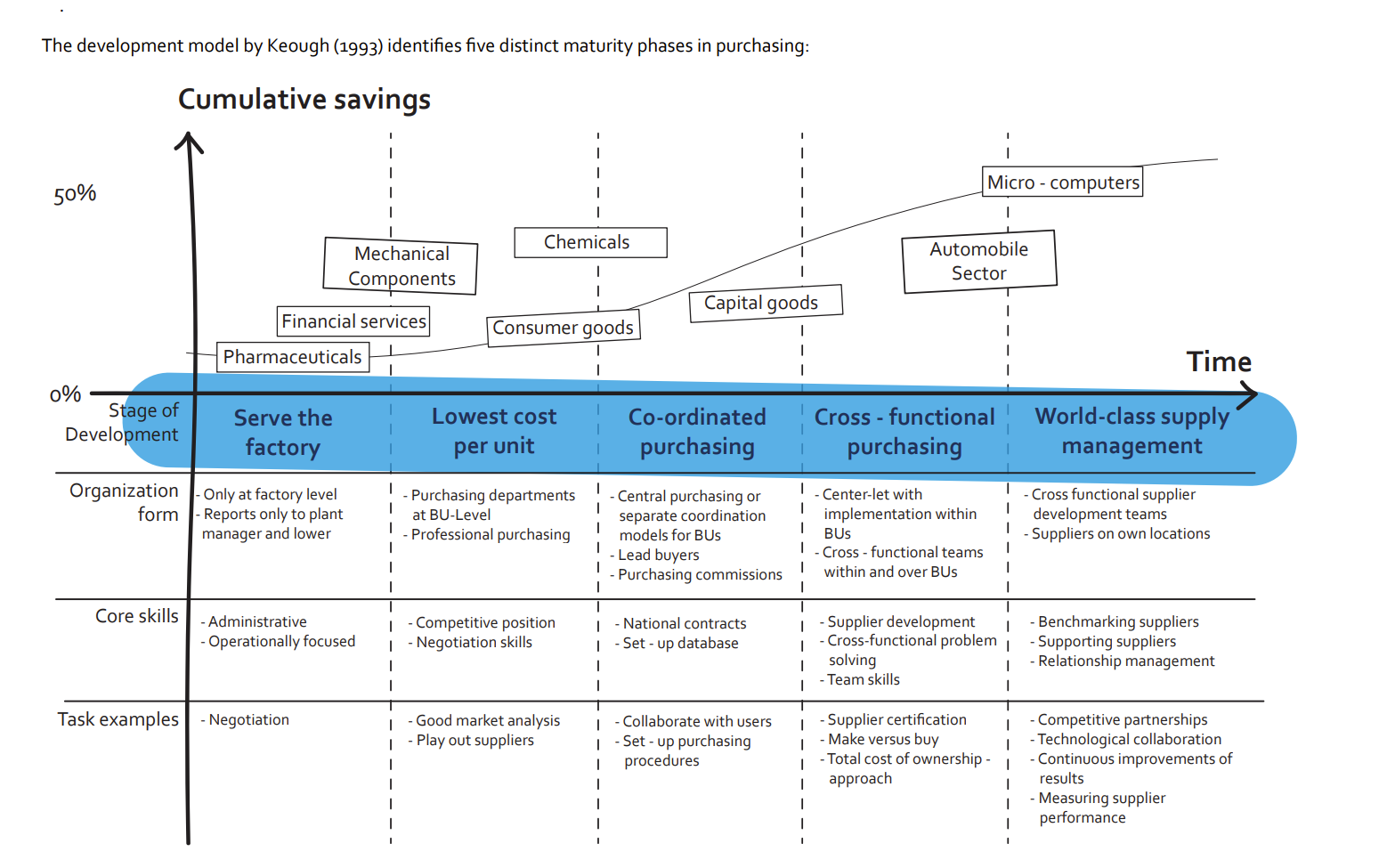

The development model of Keough (1993) distinguishes 5 different maturity stages in procurement:

Organizations who are in stages 1.5-2 will only be able to set up an effective system, but more importantly be able to successfully deploy the results.

What supplier assessment system?

There are generally 3 basic choices when choosing how to set up a supplier evaluation system:

- Excel/business intelligence tool

- A module in the own IT/ERP system

- A separate dedicated application for supplier assessment.

However, each system has its pros and cons.

1. Excel/business intelligence tool

Benefits:

- Cost efficiency is often already present

- Very flexible

- Easily accessible for all users

- Surveys are possible, but difficult to manage/administer

Disadvantages:

- Very vulnerable. Often dependent on 1 builder, who better not leave the company. Moreover, this one person is not an expert.

- Ultimately expensive in construction/maintenance

- No continuous monitoring of the suppliers.

- No user-friendly interface.

- Often no/insufficient data link. Data collection time is consuming. Not suitable for large numbers of suppliers and/or many evaluation criteria.

- Often looks cheap, which can undermine the message to the supplier

- Discipline is required and ultimately only a limited life span of the system

After visiting more than 200 companies, I can conclude that a setup in Excel in particular is not a solution. I have not seen organizations happily working with it for many years. Without exception, it bleeds to death after a few years because the builder and the discipline have left.

With a BI tool, such as Clickview or Power BI, the chance of success is greater because the system can often be fed with IT data. But again, the capabilities and knowledge remain limited, leaving the business very vulnerable.

2. Module within the own IT/ERP system

The larger suppliers of IT and ERP systems sometimes also offer an additional module for supplier assessment.

Benefits:

- Integrated, 1 solution, 1 login

- Built by professionals, looks professional. Pleasant user interface.

- Suitable for large numbers of suppliers

- Low-time investment/ready for use

- Continuity guaranteed

Disadvantages:

- Extremely inflexible, only a few criteria are available

- Generic and not tailored to the organization

- Very expensive to adapt/expand

- Exclusively based on IT data, no survey possibilities

- Often many times more expensive than a separate solution, even without adjustments

- No possibility of monitoring own purchasing performance

If the ambition does not go much further than issues such as delivery reliability, if there is more than enough budget, and if a simple/restricted IT environment is valued highly, then the purchase of an additional ERP module can be a solution. But among the real buyers and supplier assessment fetishists, to which I also count myself, the price/quality ratio for such solutions is completely lost.

3. Separate IT solutions for supplier assessment

There are also (web) solutions for supplier assessment on the market, which are built especially for this purpose.

Benefits:

- Built by professionals, looks professional, and also towards suppliers. Continuity guaranteed.

- More flexible than an ERP module; good systems can be set up completely according to one’s own needs and taste.

- Cheaper than an ERP module. Prices start at around €6,000 per year.

- Set up once, no need to worry about it again.

- Based on IT data and/or employees’ opinions. Survey capabilities.

- Analysis capabilities show the state and movement of vendors. Alerts notify the user when a supplier is out of the loop.

- Tracking of own purchasing performance is possible.

Disadvantages:

- Less flexible than Excel

- More expensive than Excel

- More setup time is needed than an ERP solution

- Additional login for the users

From the above, it can be concluded that, if the ambitions and scope are somewhat serious, a separate solution for supplier evaluation offers the best value for money.

If you summarize the above, the following table emerges, which can serve as a rough guide: